Robot see robot do

Team

IAAC MRAC 2022

Date

2022.3

Contribution

Fabrication, Tool path generation

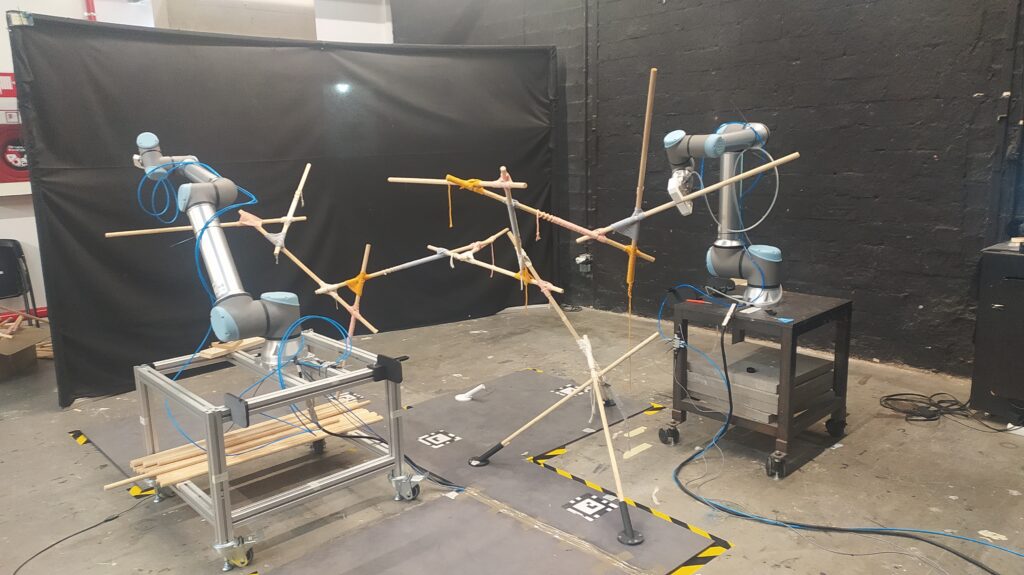

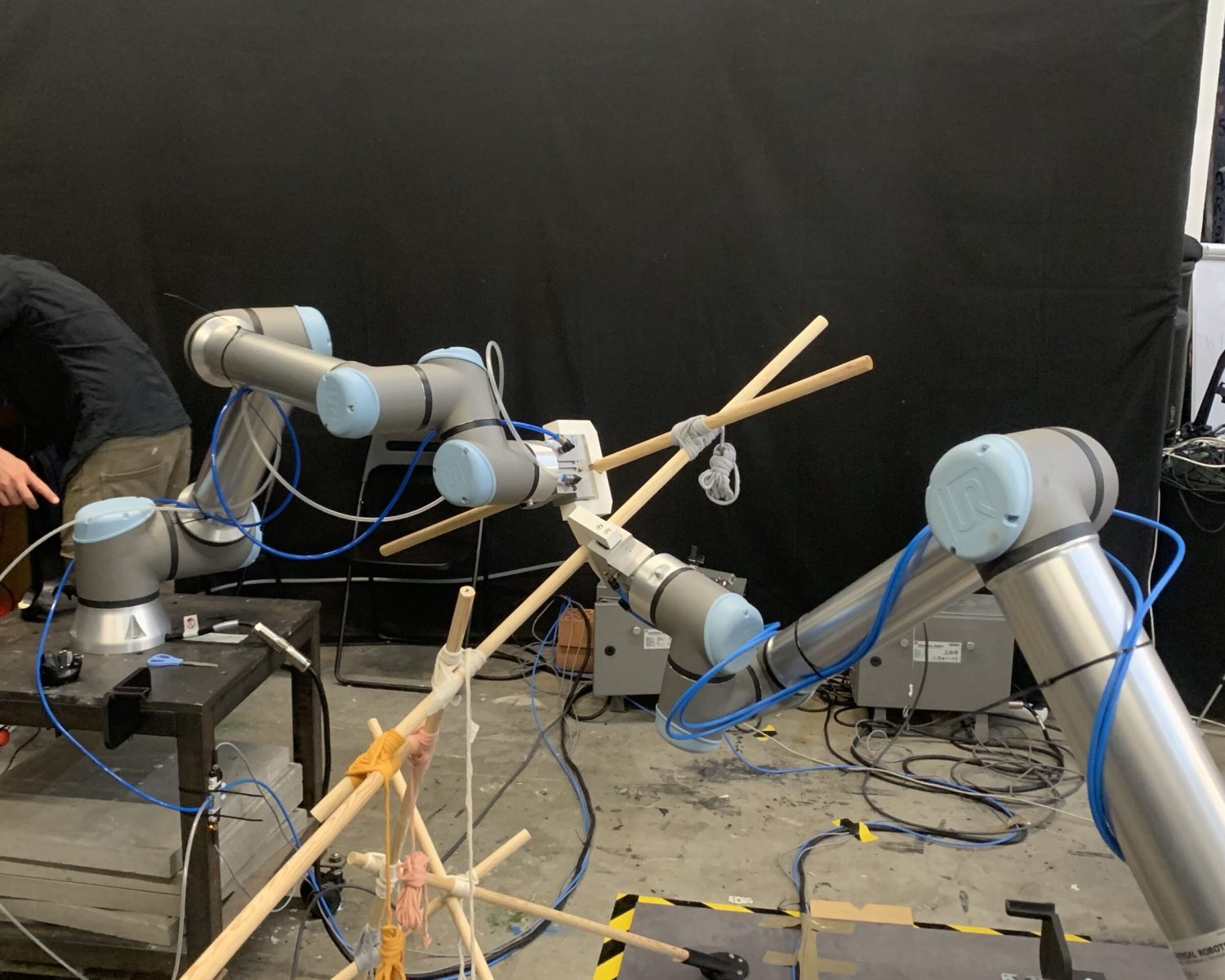

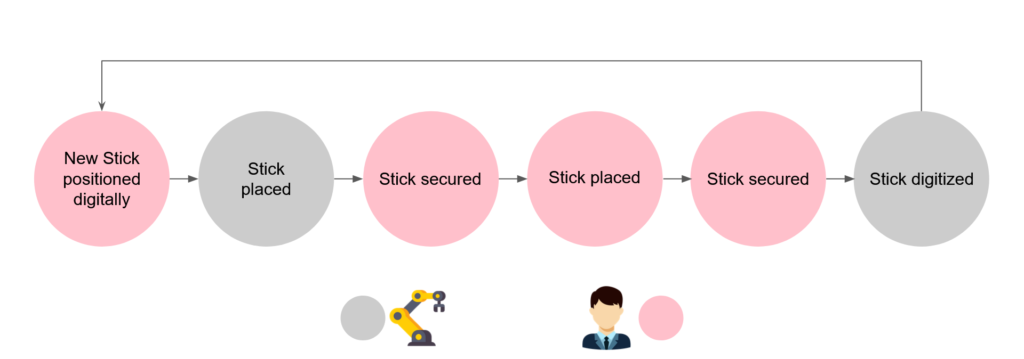

Digital fabrication technology has opened up the possibility to fabricate directly from design information, promising to transform many design and production disciplines in the Architecture, Engineering, and Construction (AEC) sector. However, the unstructured nature of construction poses several technical, social, and economic barriers that hinder the direct adoption and integration of such innovations by the AEC sector and the achievement of the vision of fully automated and robotized building construction. Hence, in this workshop, we investigate whether the idea of a hybrid, dually augmented human-robot partnership could form the basis of a paradigm shift in this field. Human-in-the-loop design and production chains have the potential to exploit machine intelligence and capacities while incorporating the participatory engagement of builders and fabricators.

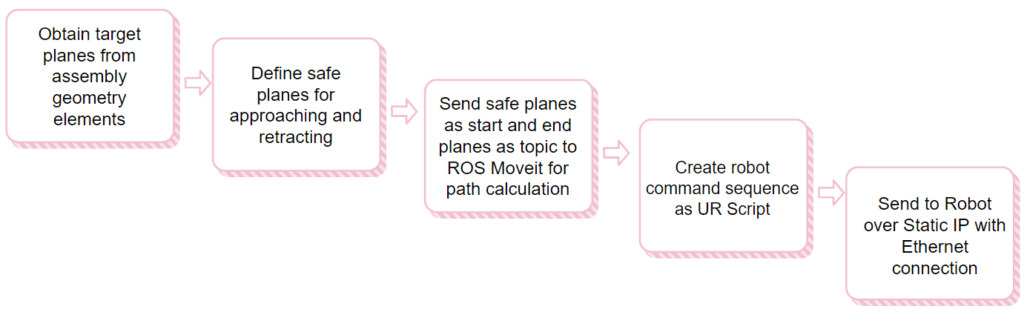

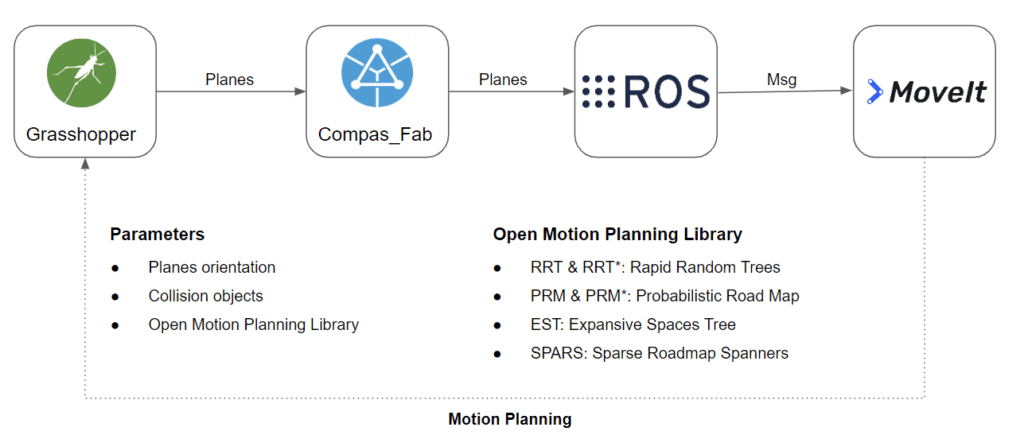

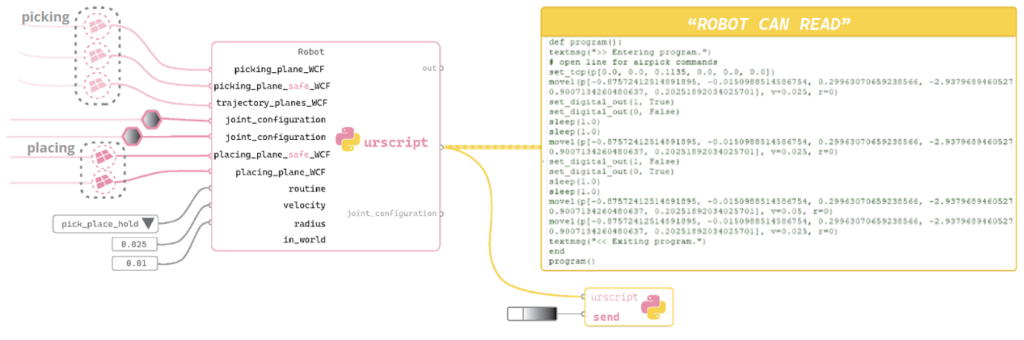

Plane and toolpath definition

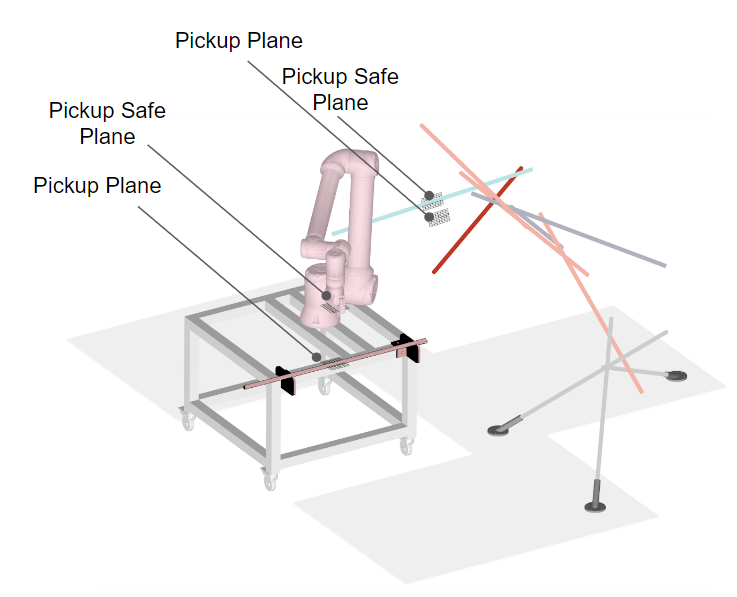

From the design phase, we obtain the placing planes

From the robot setup, we have the pickup planes already – the pickup place is always at the same place relative to the robot

Using COMPAS transformations, we define the safe (approach and retract) planes by moving along the respective Z-Axes

Plane and toolpath definition

We define the following as collision objects:

- The robot table frame

- The sticks in the assembly

- The movable stick attached the the robot gripper

- The robot body

To push conceptual and technological boundaries in this domain, this workshop explores the potentials of human-robot collaboration for the in-place assembly of complex building structures. By using a custom-made object-aware mobile AR interface, humans and robots share a digital-physical workspace, in which humans are informed by digital spatial data, and robots are informed vice versa by the information of tracked physical objects for cooperative assembly routines. In doing so, we aim to negotiate the levels of task distribution and coordination and reinvent the fundamental relationship between humans, machines, and robots.

As part of the overall assembly, this group was tasked with determining and implementing a lashing system that would be both easy to teach to the rest of the workshop and quick to execute as so not to delay the fabrication process, but most crucially would provide a structural connection to each of the nodes, whilst allowing for flexibility in a system that shifts over time and adding aesthetic value.