Mesh topology

Team

Huanyu Li, Alfred Bowles, Mit Patel

Date

2021.10

Contribution

Geometry design, Script development

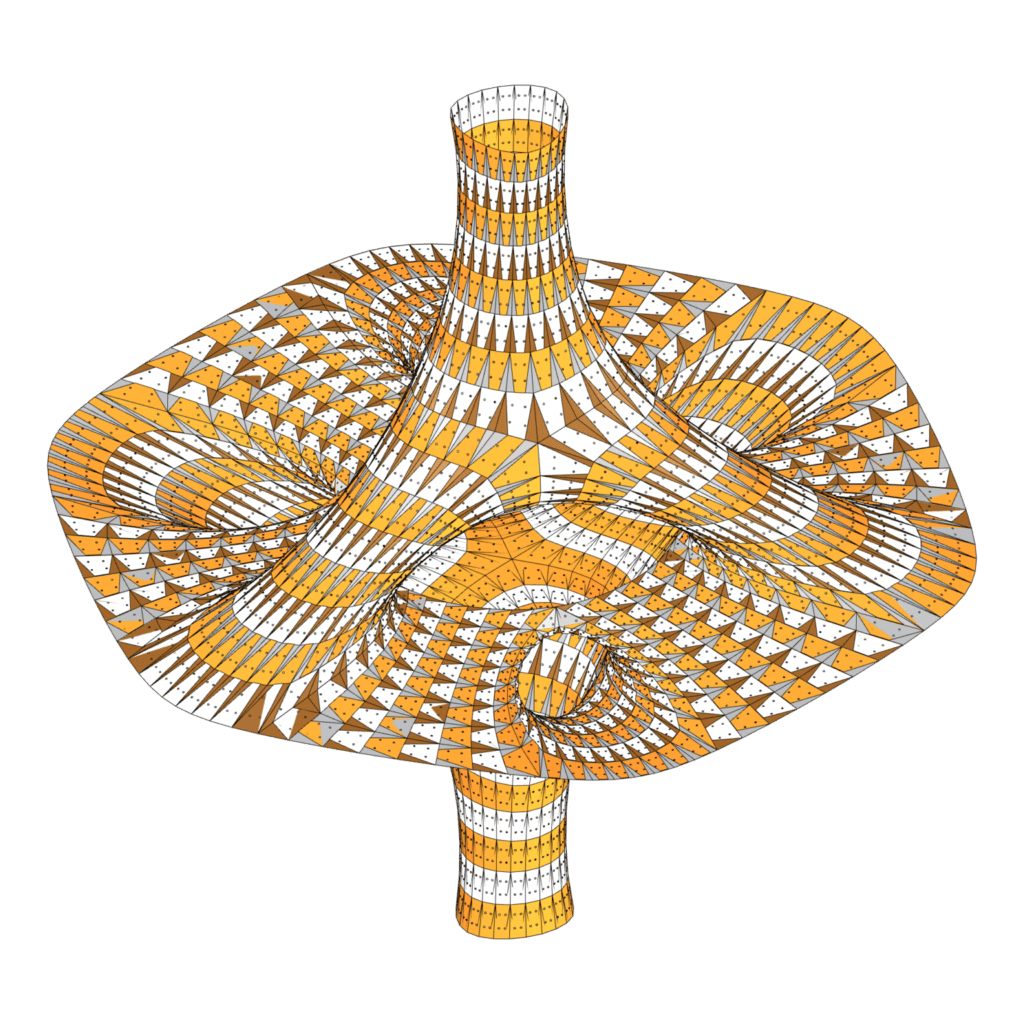

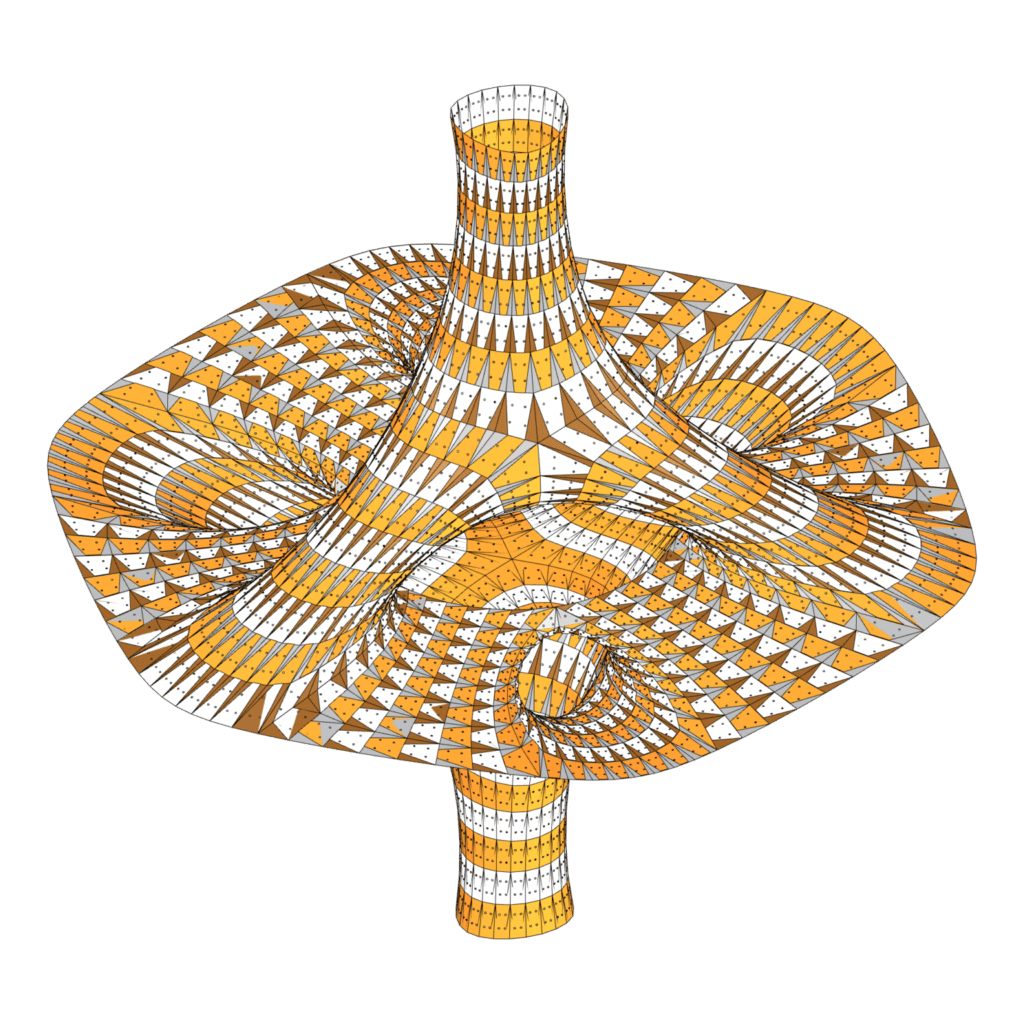

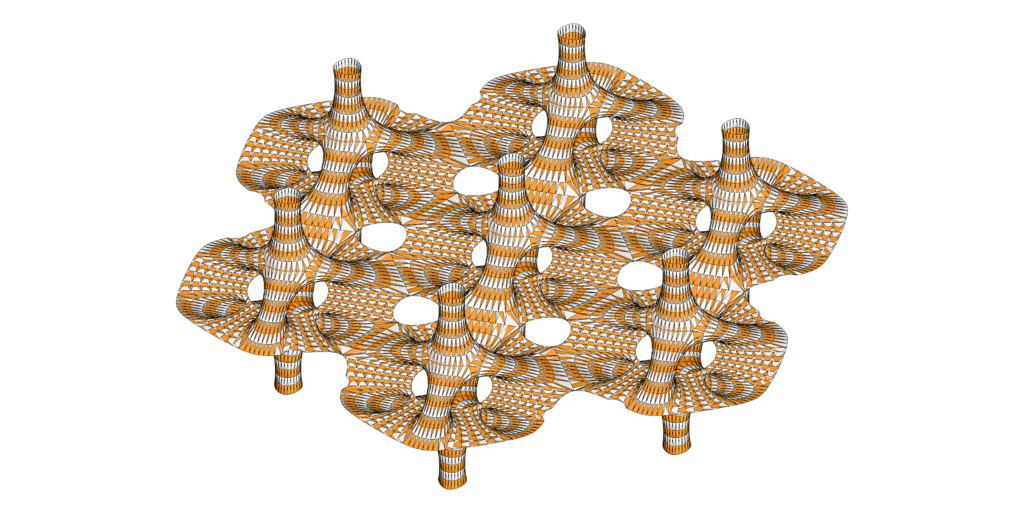

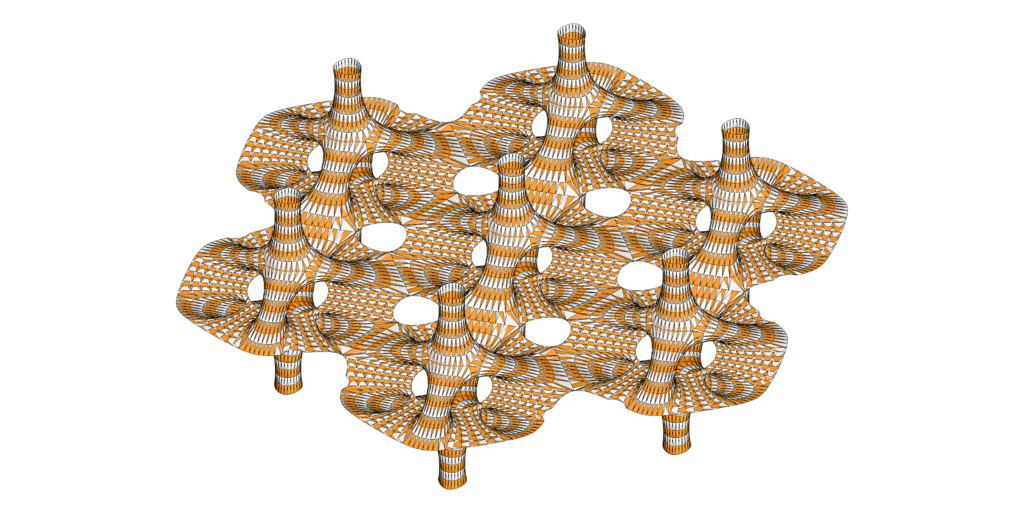

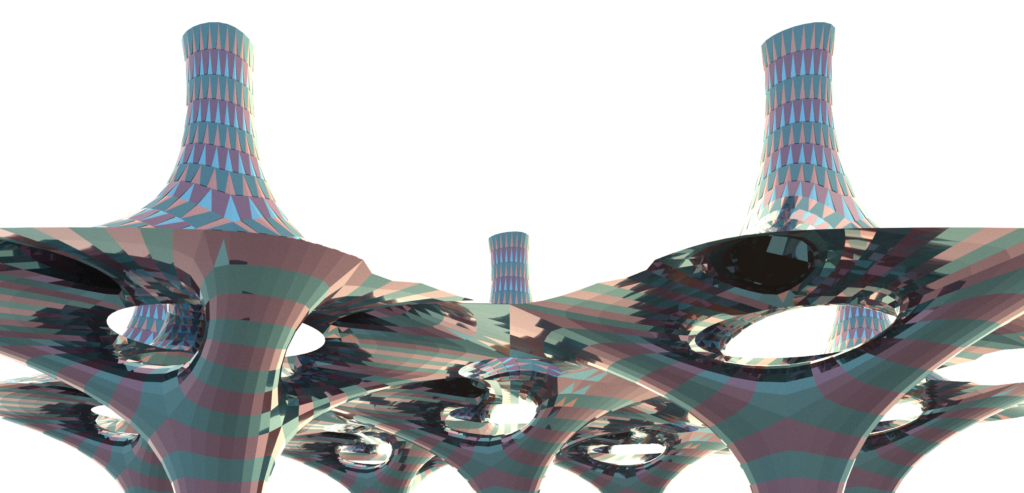

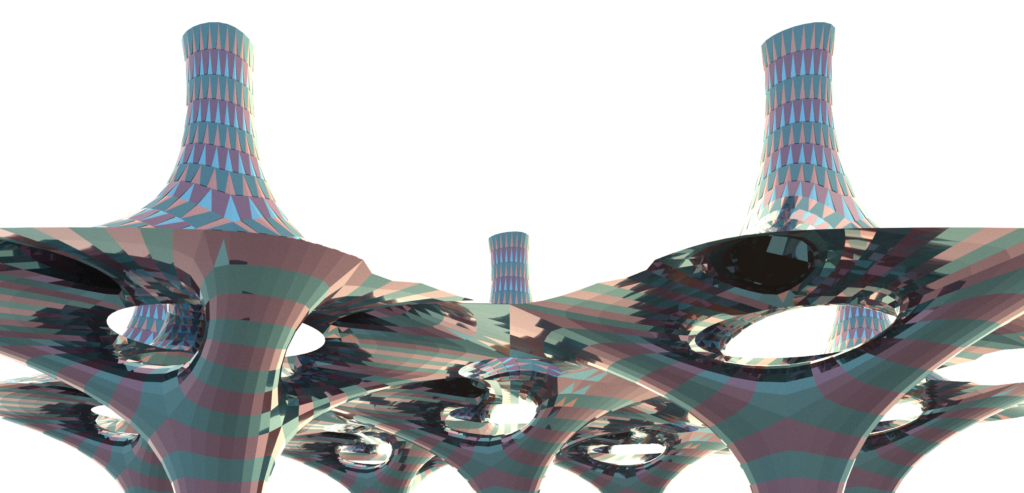

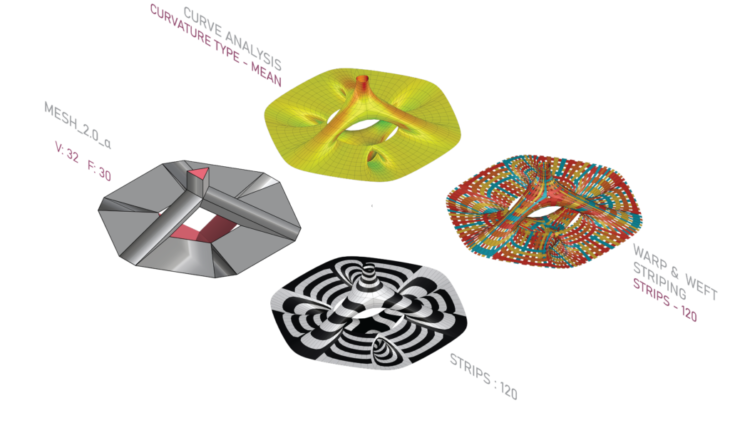

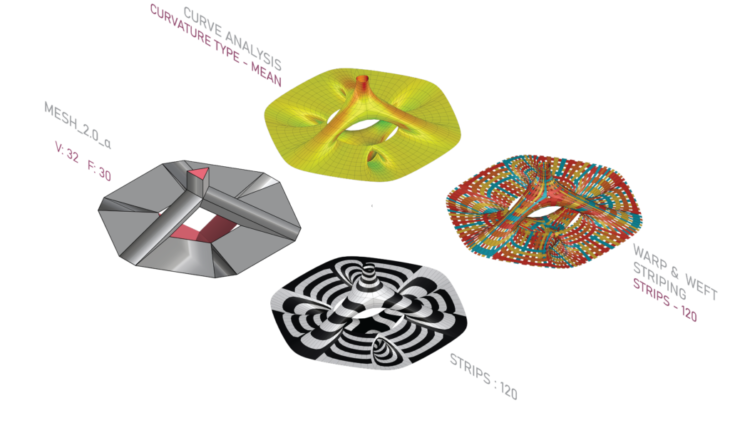

An exploration in meshing using low-poly subdivisions as a primer for mesh subdivision and relaxation. through this process the user can generate and control complex geometries and patterns starting from relatively simple triangular and quadrangular mesh faces. it sets a scripted environment with the primer at its very core changing and creating geometric patterns

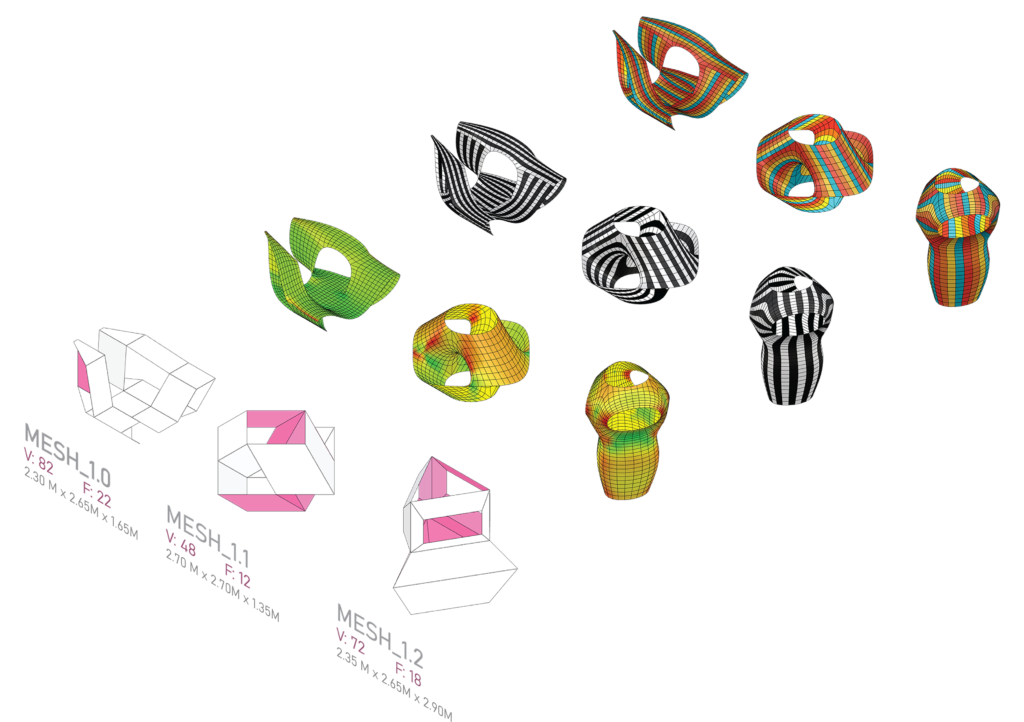

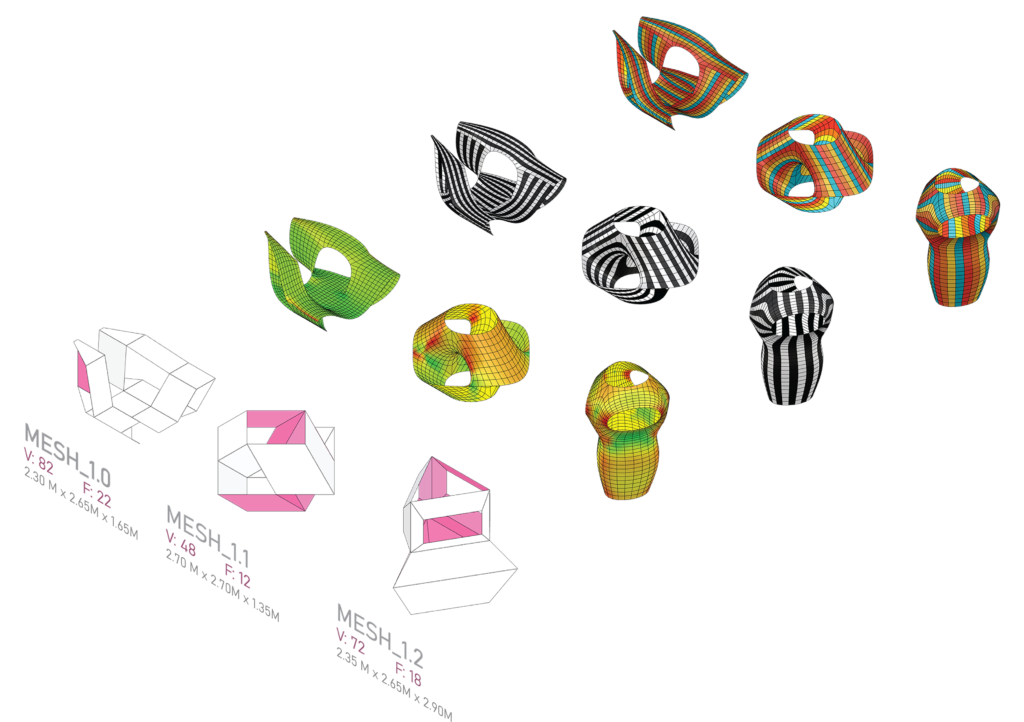

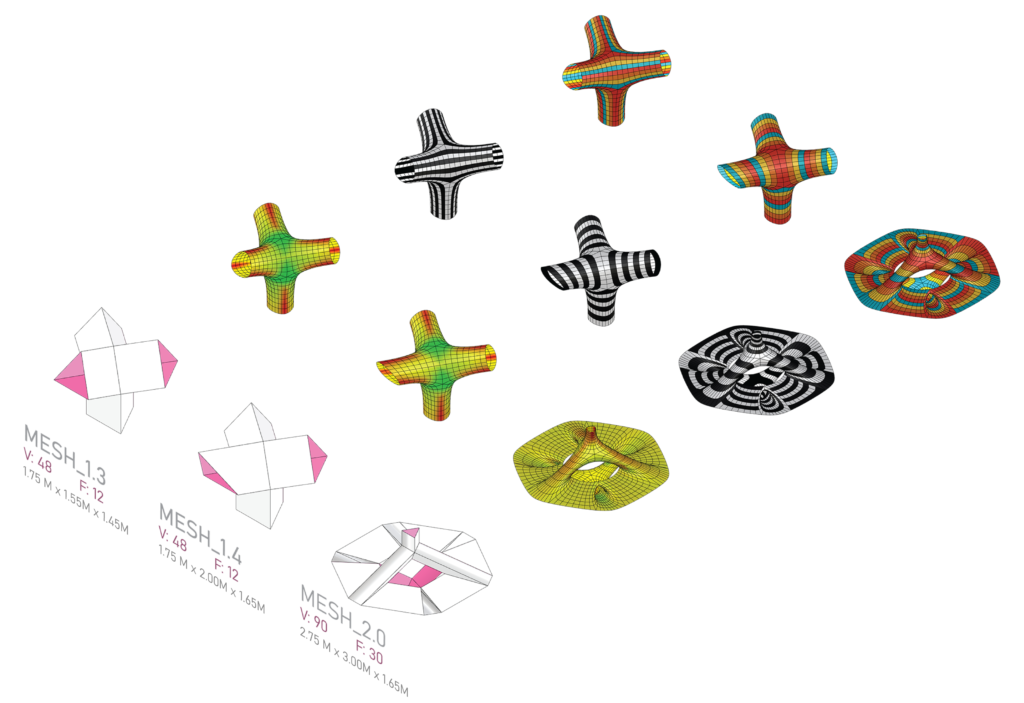

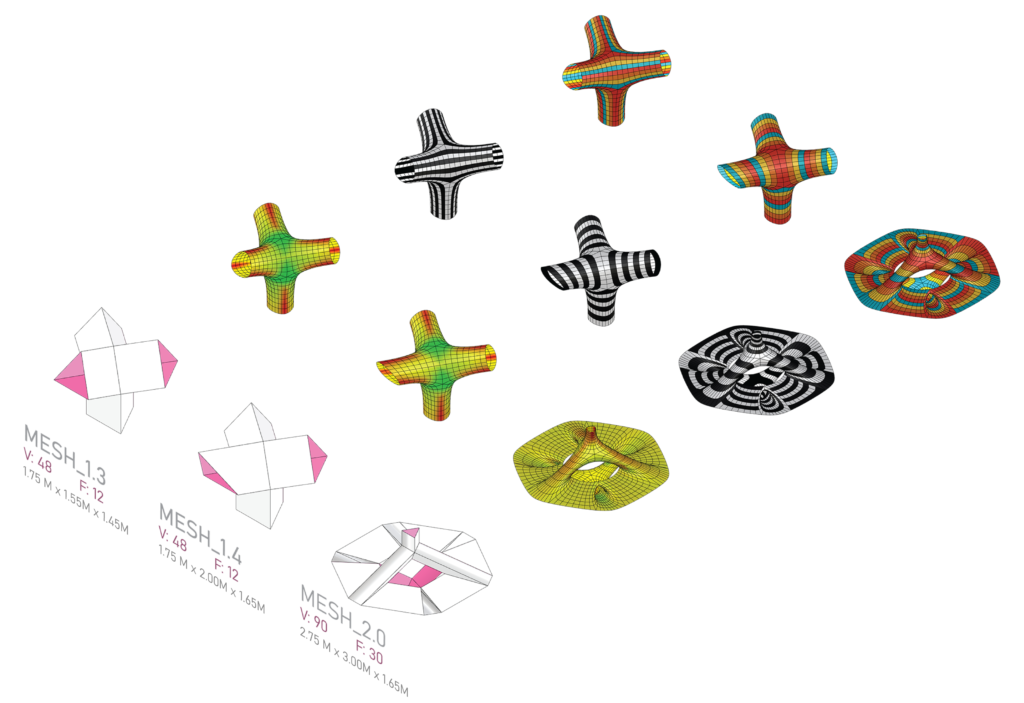

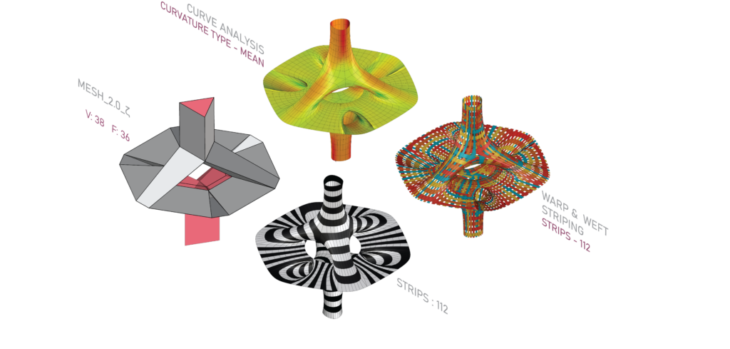

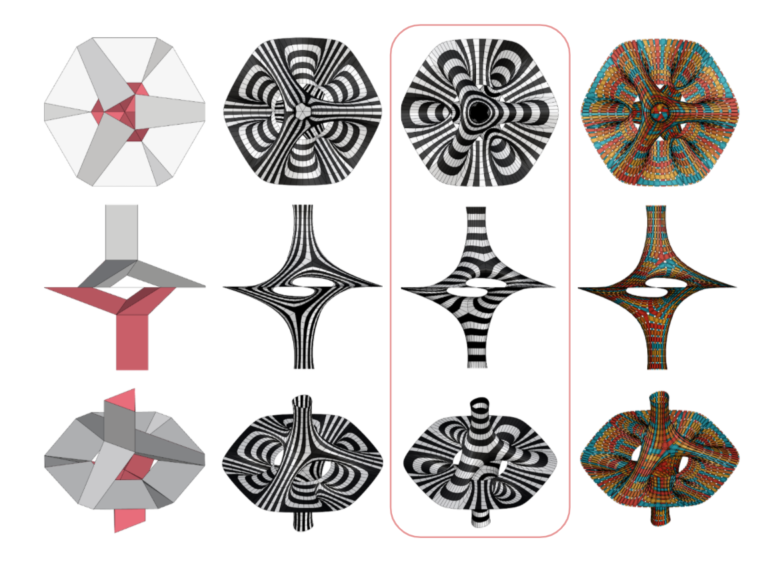

We start by setting up our script for mesh relaxation and striping, and begin exploring 6 different low-poly mesh options.

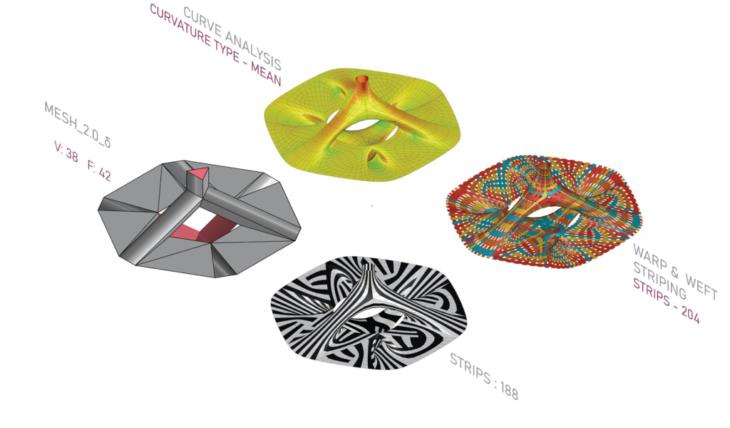

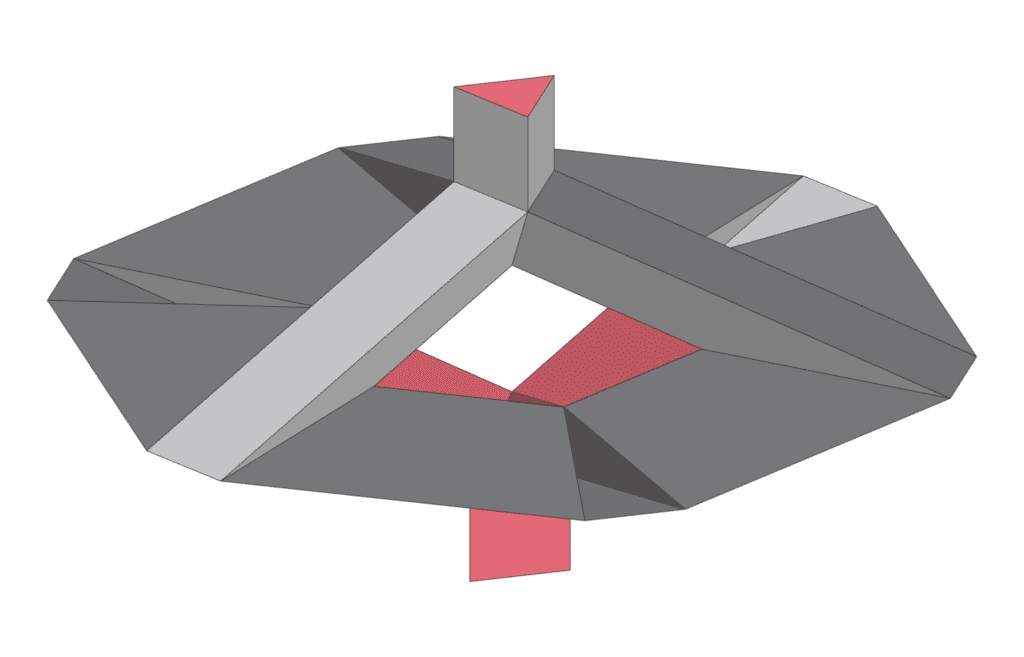

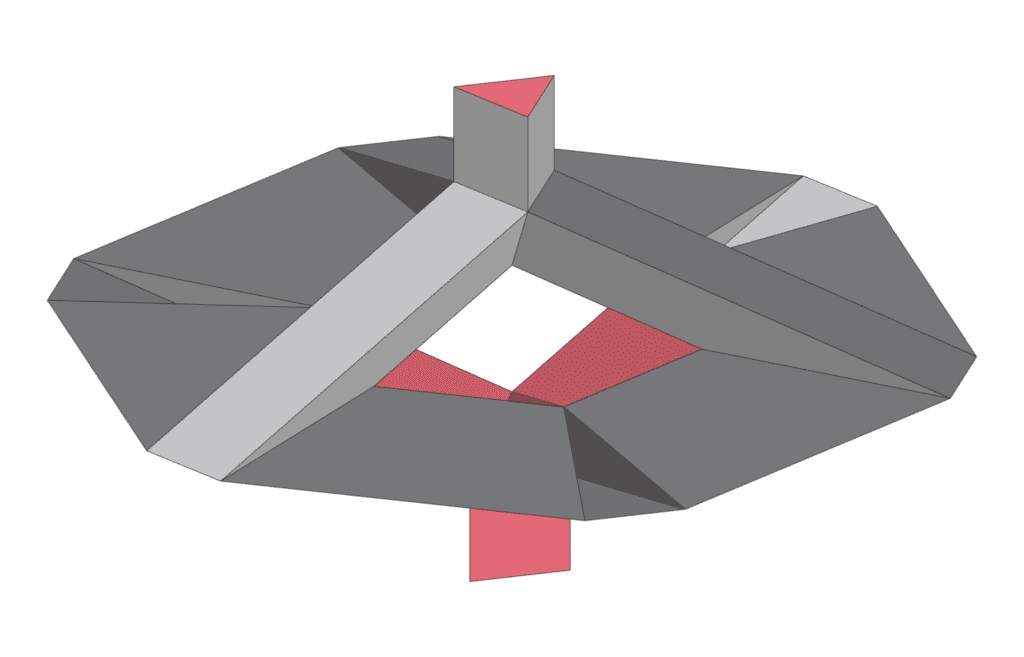

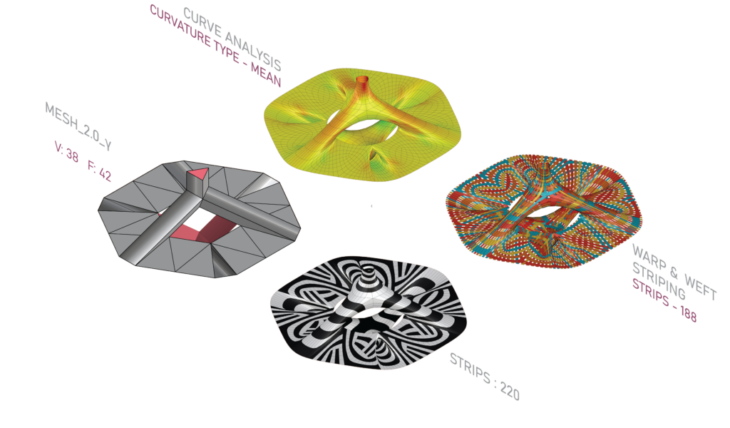

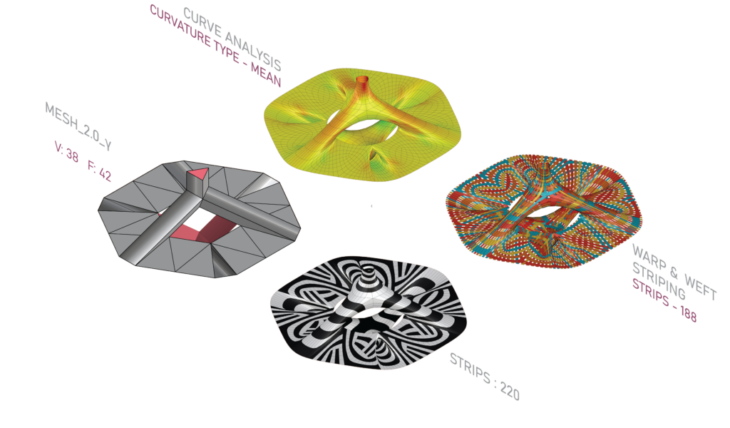

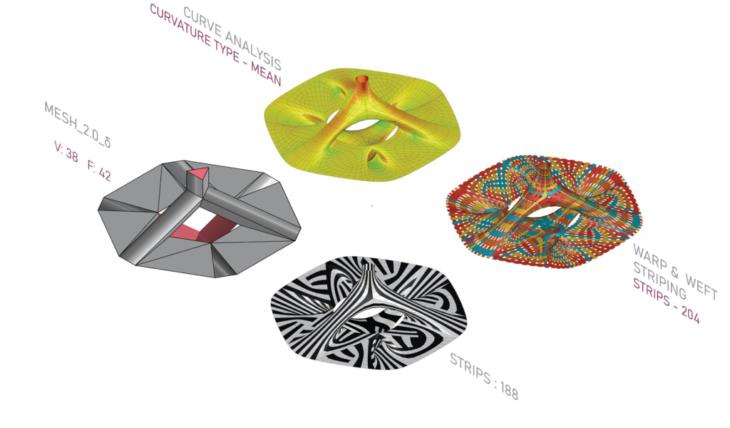

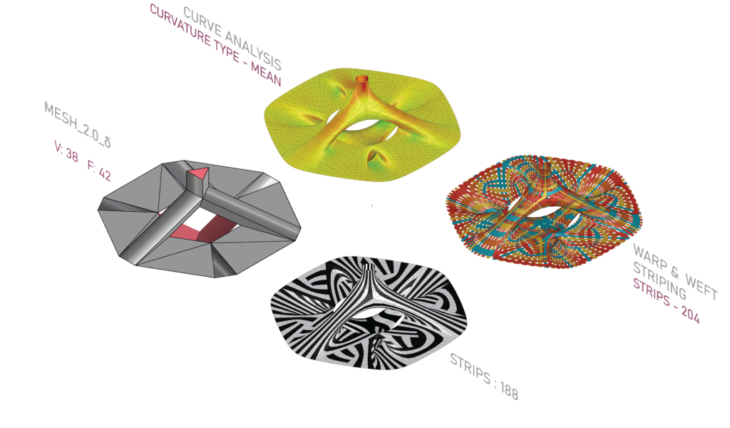

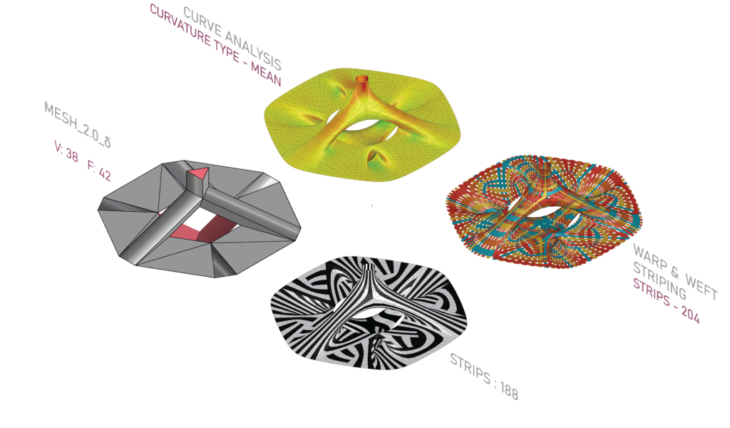

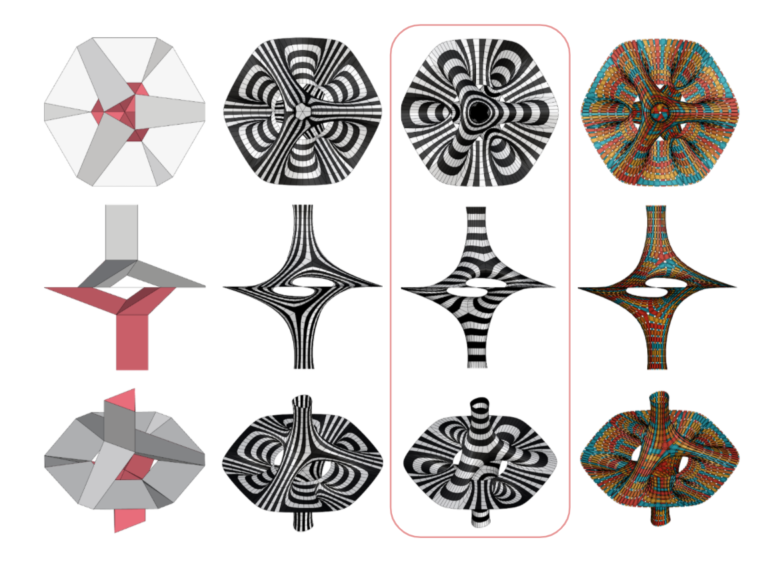

At this point, we choose Mesh 2.0 to go forward with based on the following criteria:

- Curvature factor at all points of the surface are relatively low, meaning easier manufacturability

- The intersecting geometries and tube shaped faces offer many possibilities for repeatable pattern generation

- Hexagonal plan section allows for interesting repetition for multiple units in all directions

- Controlling the initial topology by having only quad mesh faces allow for easy manipulation and organization of the strips

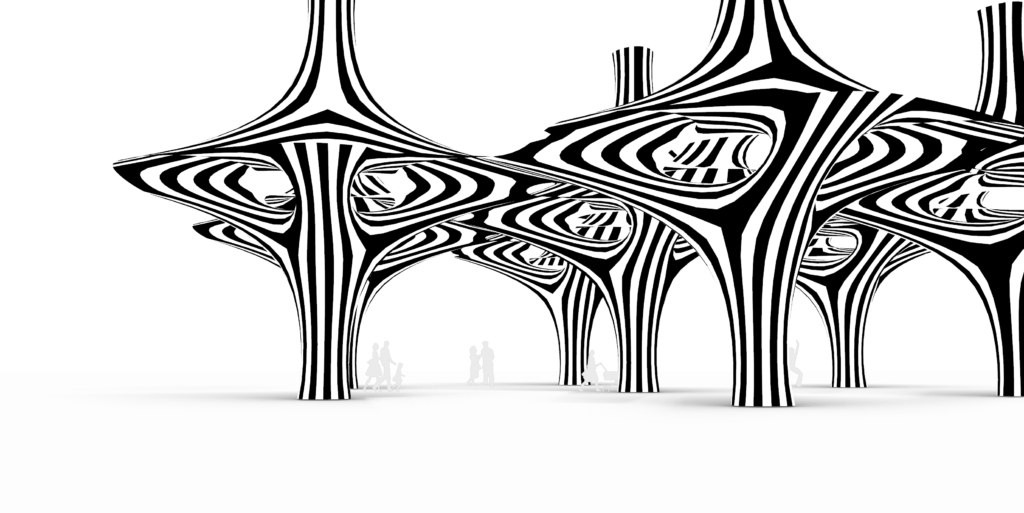

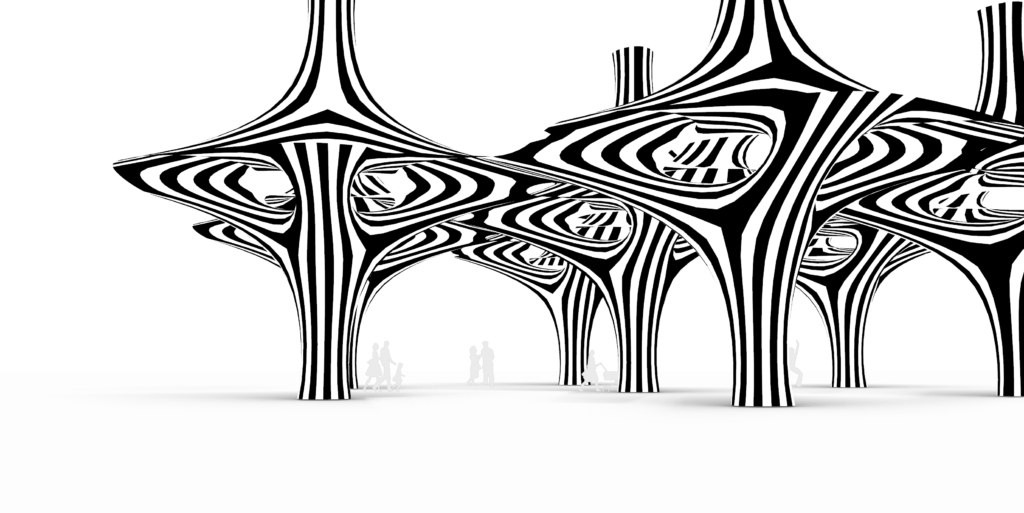

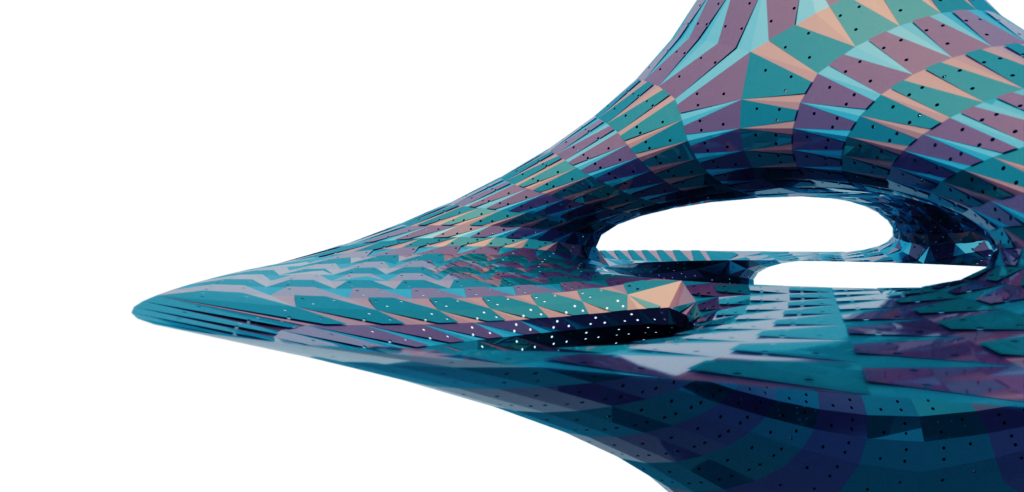

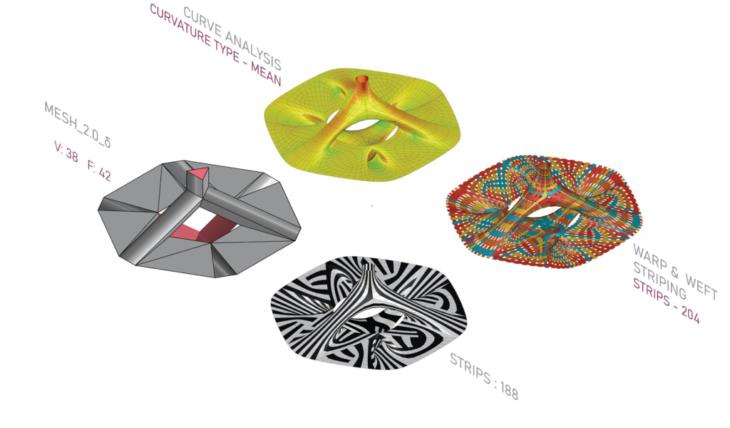

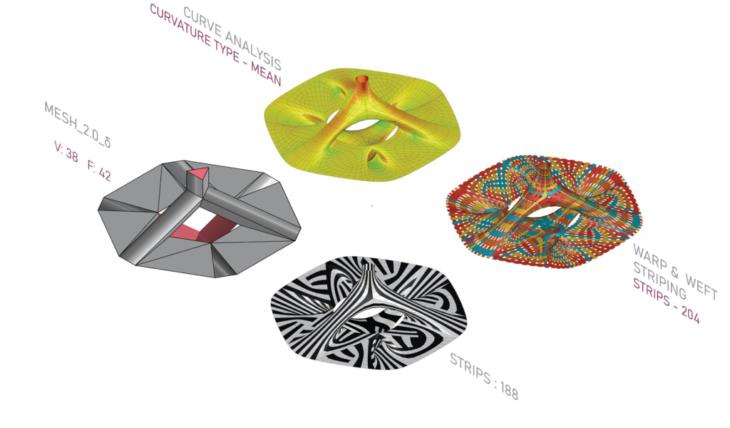

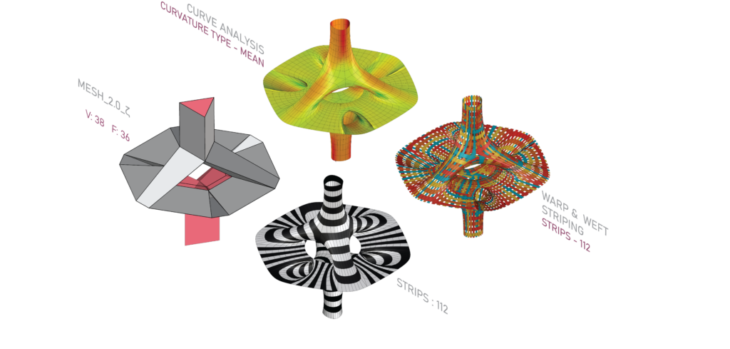

- Beginning to divide our mesh into triangles on the tube shaped faces, we start to get interesting patterns going along those directions. Strip number increases because triangulation breaks continuity.

- Increasing the number of subdivisions and triangular faces, we start having very interesting patterns. Continuity greatly decreases and the number of stripes almost doubles. We also start having a contrast between wide stripes where we have less initial subdivisions and thinner stripes in areas with higher subdivisions

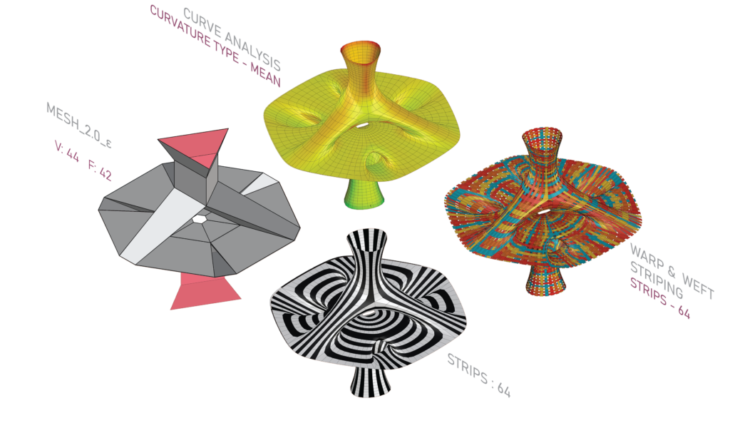

- Dividing the larger faces, we can maintain continuity on the tube shaped faces, but start to have discontinuous patterns on the flat faces. Strip number increases as more discontinuity is occurring.

- Adding offsets to the internal edges as well as the top and bottom faces, we can increase the surface area and get more repetition. Despite having a larger surface area, orienting the faces to be more linear, we get very high continuity and the number of strips drops dramatically to 64, but strip length also increases.

- With wider tubular faces, and a bigger top and bottom, we can achieve a more desirable stable structure. Retaining only quad faces, we are able to organize the strips with ease for fabrication.

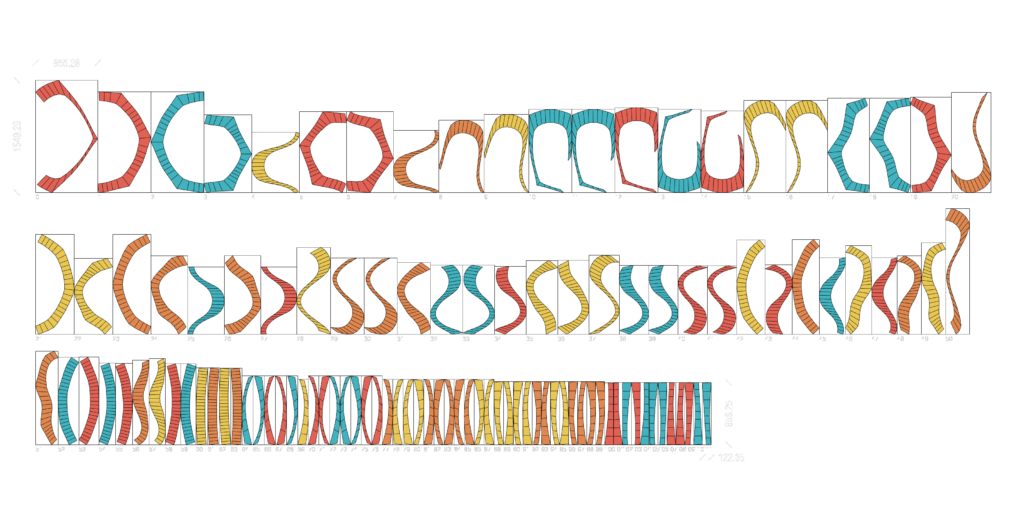

Using the OpenNest plugin, we nest the strips onto three 4400 x 2500 mm sheets which is the bed size of a GWEIKE LF3015LN – Fiber Laser cutting machine which we used as a referencex`

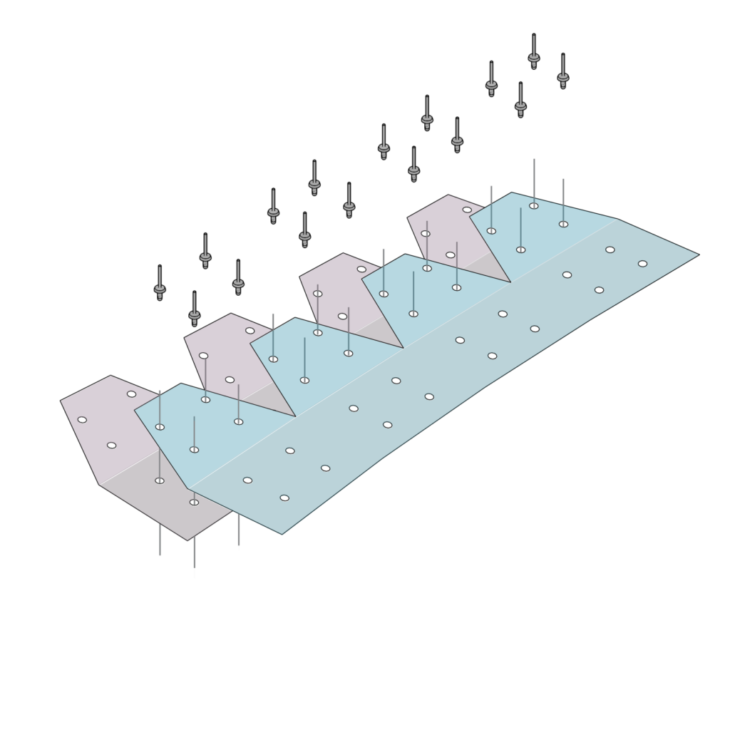

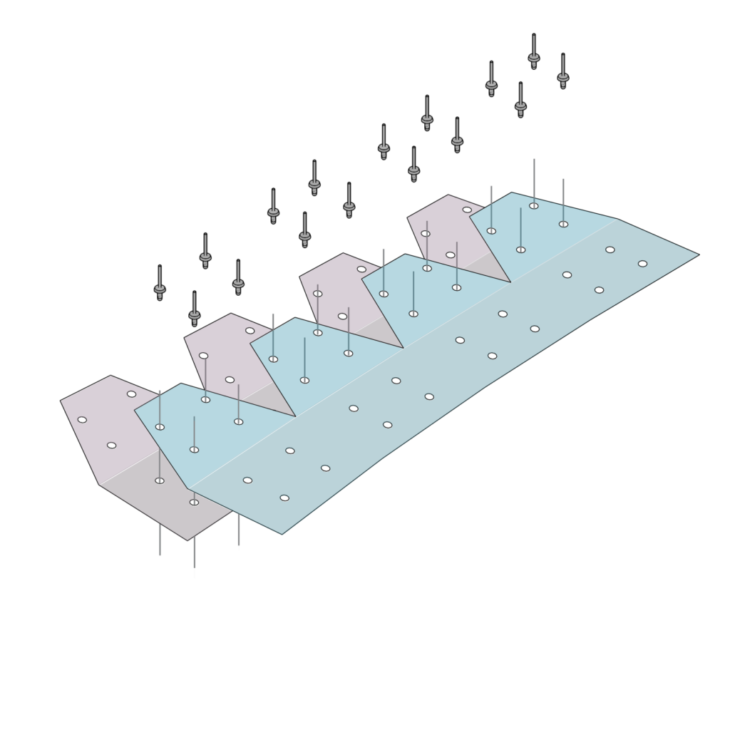

DragonSkin, a fabrication design strategy developed by overlapping subsequent strips with trapezoidal flaps and riveting them. This method can facilitate fabrication and creates a striped scale-like aesthetic for the Final Mesh Iteration that was selected