3D printing clay extrusion study

Team

Huanyu Li, Abanoub Nagy, Shazwan Mazlan, Paco Pioline

Date

2022.9

Contribution

Fabrication, Tool path generation.

Machine was an introductory workshop to introduce technologies, techniques, and materiality on deposition modeling and its implication in the design.

With the setup of a standard form that could return in various shapes, research groups experiment with different parameters of the material itself or the machine. The result is a matrix of primary geometries with different characteristics from which could be extracted machine parameters and setup conclusions.

Viscous enough, it needed to reach its perfect plastic state in order to be extruded – exploration was designed using only clay. The tactile sense was an important decisional factor in creating the ideal paste made of clay powder and water.

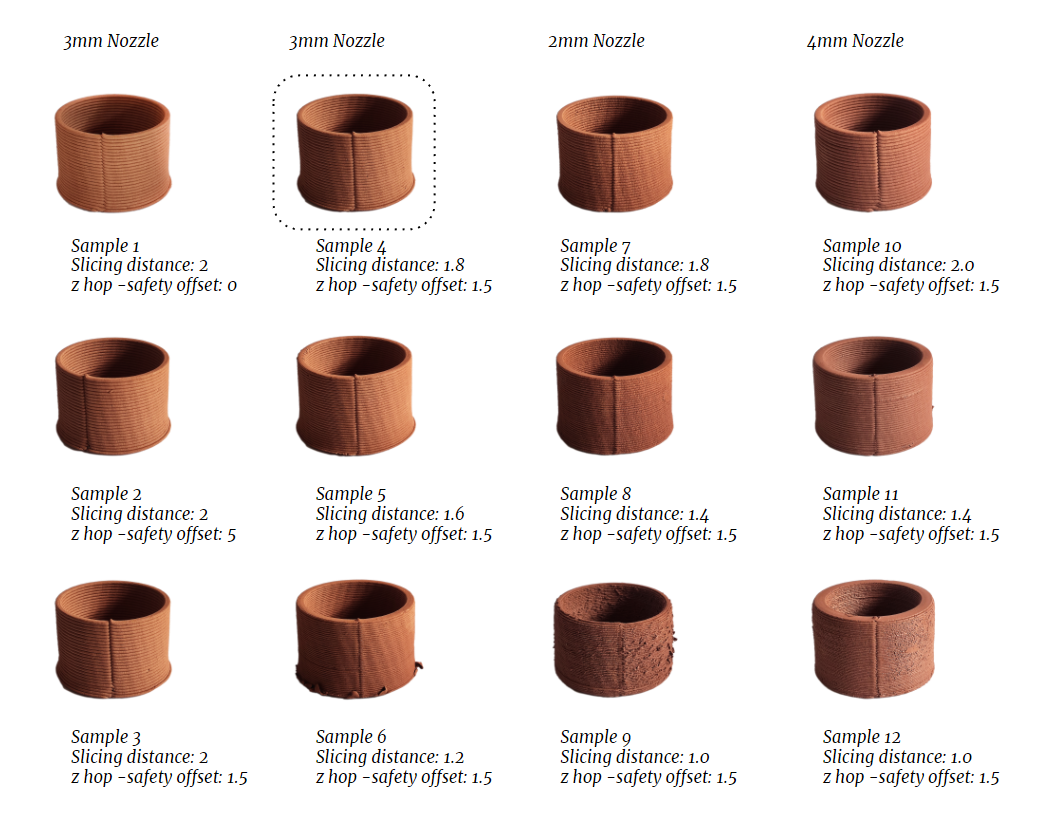

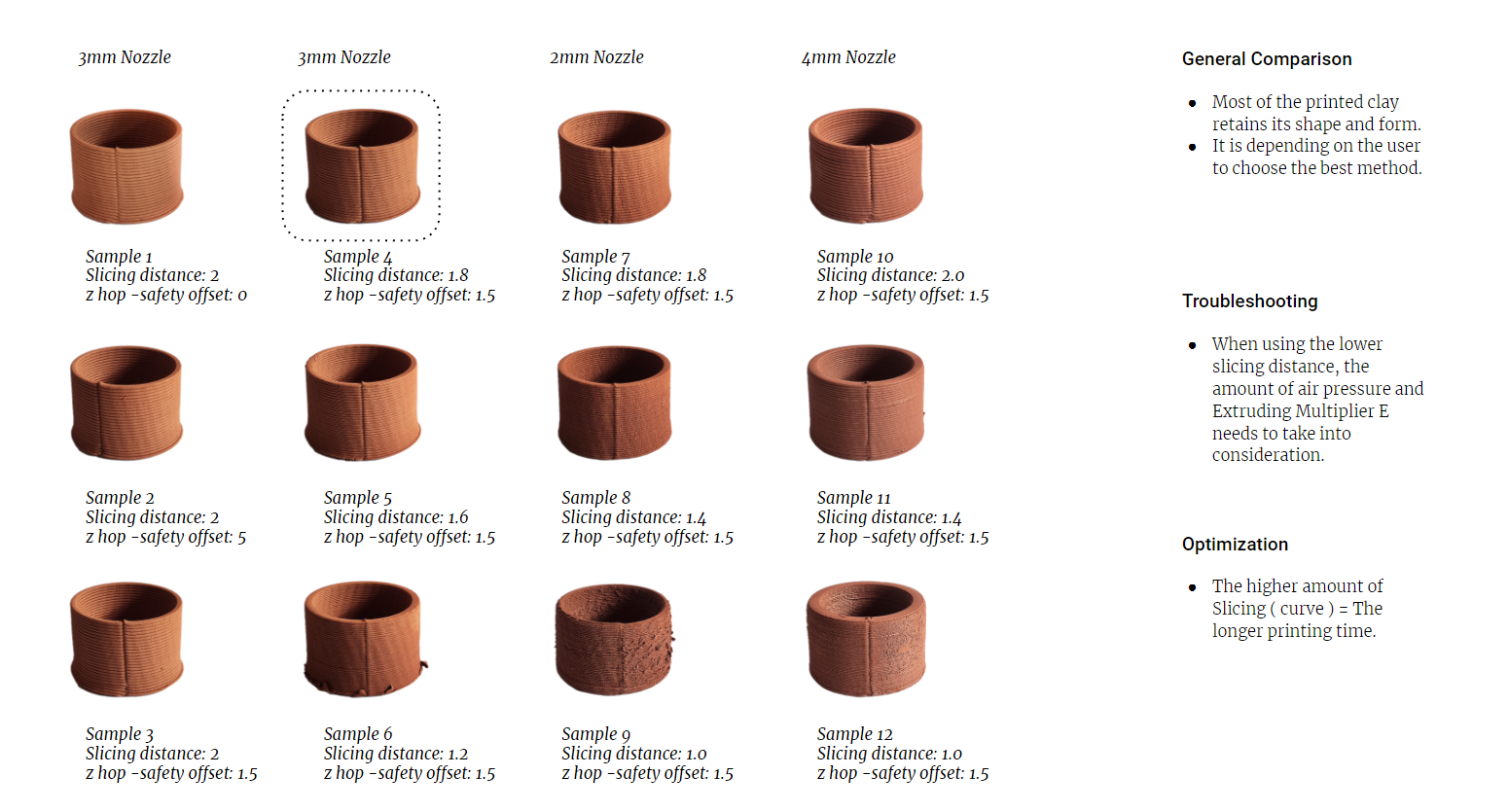

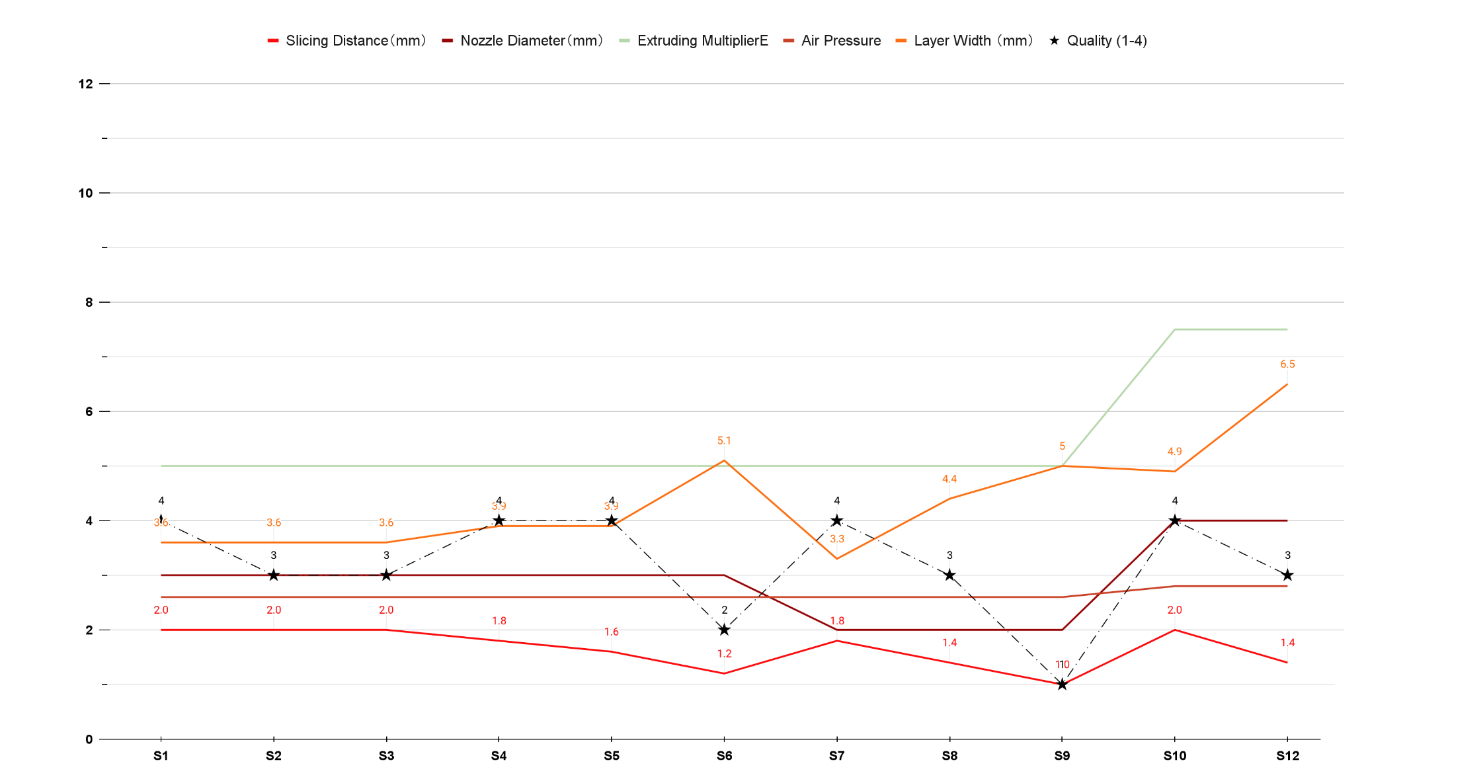

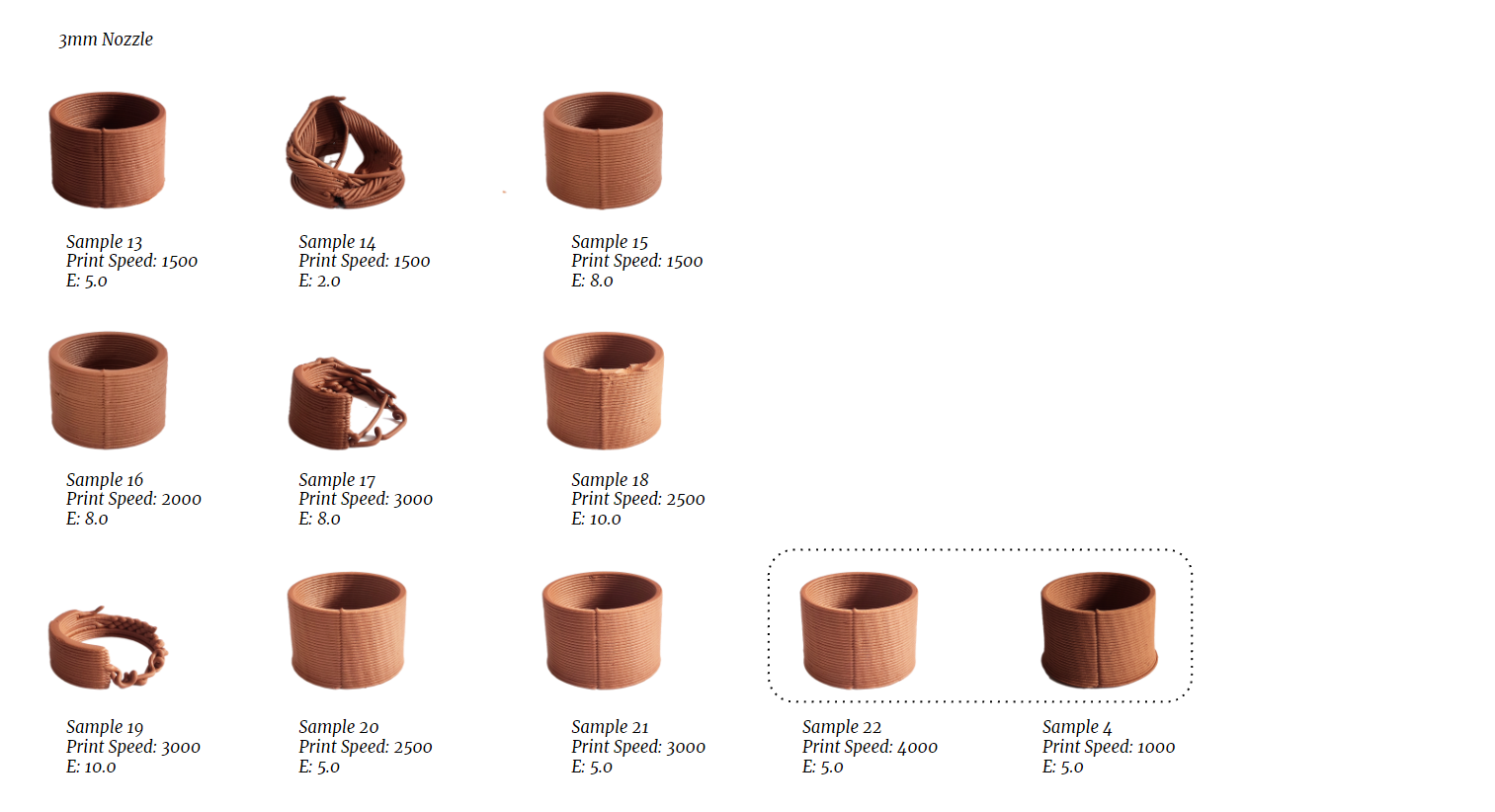

Setting up the machine with only the following nozzle diameters (N) ⌀2 / 3 / 4mm led us to define a ratio between them and the slicing distances (Sd) and explore its questionable similarity and applicability in a larger scale prototyping. Thus, for a more optimized conclusion, the sliced geometry was defined by a ratio (Sd/N) of ca. 0.5 / 0.7 / 0.9 / 1.0 for every nozzle diameter available – resulting in various slicing distances, always maintaining the rest of the parameters at the same rates.

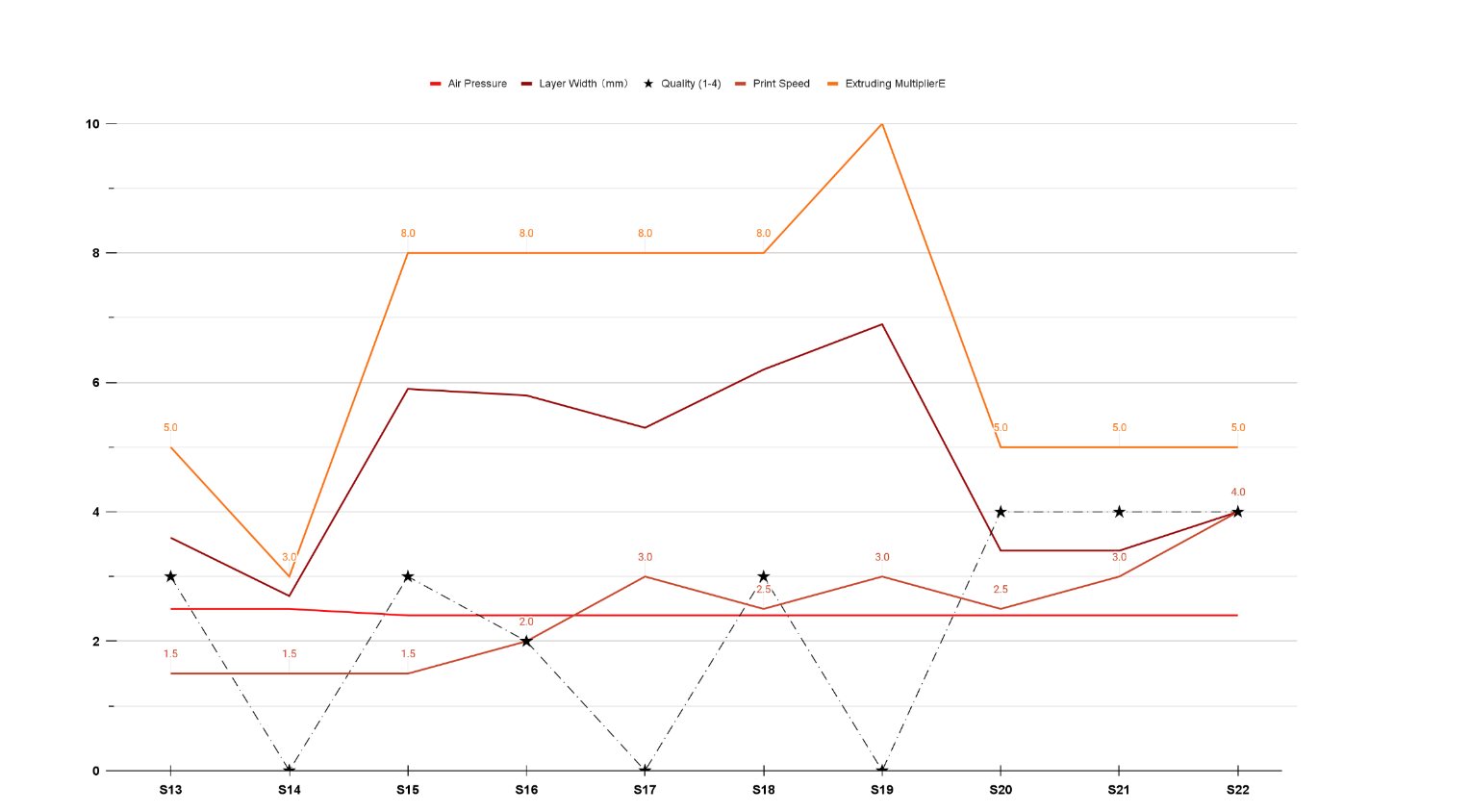

Example of printing parameters:

- Feedrate (F mm/s): 1000

- Jog Speed: 4000

- Extruding Speed (E): 5

- Retraction Setting: 0

- Safety Offset: 5

- Pressure (Bar): 2.5

After printing multiple samples, the evaluated 3D printed clay iterations drove to the conclusion that a ratio close to 0.5 is better to achieve the best results in pieces. This conclusion was made considering aesthetics and structural factors such as lesser cracks in the extruded material, or thicker connection between the layers.

Conclusion

Maintaining a ratio (Sd/N) between the slicing distance (Sd) and nozzle diameter (N) under or equal to 0.5, increasing the feedrate to 4000 mm/s and setting the printing in continuous spiral toolpath results in a coherent print with a good aesthetic and good potential static behavior due to the impeccable connections between its layers.

Strategies were needed to overcome a myriad of printing challenges and inconsistencies in extrusion. Most of the inconsistencies were related to the material or printer hardware, including air in the mix, material excessively dry, slow motor speeds, connection issues between the printer and the software, or pump exhaust.

7 thoughts on “3D printing clay extrusion study”

I just like the valuable info you provide for your articles.

I’ll bookmark your weblog and check again right here regularly.

I’m slightly certain I will be informed plenty of

new stuff right right here! Best of luck for the next!

Thank you!

Wonderful site. Lots of useful info here. I am sending it to

a few pals ans also sharing in delicious. And naturally, thank you in your sweat!

Thank you very much! It’s also my pleasure that my research could inspired people like you. I’ll keep posting my work and welcome to leave your comments!

Hi mates, its impressive article about cultureand completely defined, keep it

up all the time.

Hi there, all the time i used to check weblog posts here early in the dawn, since i

enjoy to learn more and more.

my web-site; John E. Snyder

Appreciate it!